A Friction Fit Tuck Flap is a type of box closure system that utilizes friction to create a secure seal. These flaps are essentially the extensions of the main panels of the box. To close the box, simply bend the flaps inwards along the pre-scored lines and tuck them into designated slots or matching panels on the opposing sides of the box. The snug fit of the flaps within these slots creates friction, which holds the closure securely shut.

Advantages of Friction Fit Tuck Flap

Ease of Use

A Friction Fit Tuck Flap prioritizes user convenience. Forget fiddling with glue, tape, or complex locks. These closures open and close smoothly, requiring minimal effort from the customer. This creates a frustration-free experience that enhances brand perception.

Cost-Effective

From a manufacturer’s perspective, a Friction Fit Tuck Flap translates to cost savings. Friction Fit Tuck Flap’s design eliminates the need for separate adhesives or additional locking mechanisms, streamlining the production process. This reduction in materials and labor results in lower per-unit costs.

Sustainability

Eco-consciousness is a growing concern for both businesses and consumers. A Friction Fit Tuck Flap contributes to a greener packaging approach. By eliminating the need for glue or extra locking mechanisms, they use less material overall.

Premium Look

Friction Fit Tuck Flap offers clean and flawless closures, contributing to the sophistication of your packaging. The absence of visible glue lines or bulky locks creates a sleek and high-quality aesthetic. This premium look can increase the perceived value of your product and make it stand out on the shelf.

Versatility

The beauty of a Friction Fit Tuck Flap lies in its adaptability. Friction Fit Tuck Flap can be configured to work with various box shapes and sizes. Whether you’re packaging a delicate gift or a larger clothing item, a well-designed friction-fit closure can provide a secure and aesthetically pleasing solution.

Disadvantages of Friction Fit Tuck Flap

Security Concerns

A Friction Fit Tuck Flap primarily relies on friction to create a closure. This can be a limitation for very heavy or high-value products. For example, imagine a box containing a delicate and expensive watch. A glued or locked closure might offer a more tamper-evident and secure seal compared to a Friction Fit Tuck Flap, which could potentially be opened and resealed without detection.

Re-sealability

A Friction Fit Tuck Flap is designed for single-use closures. While a Friction Fit Tuck Flap can be reopened and reclosed, repeated opening and closing can weaken the fit over time. This might not be ideal for products that require frequent access, such as a container for storing headphones.

Product Compatibility

A Friction Fit Tuck Flap may not be suitable for all products. For items requiring a very tight seal, such as those containing liquids or food, a different closure method might be necessary.

Design Considerations for Friction Fit Tuck Flap

Material Selection

Choosing the right material and rigidity for your Friction Fit Tuck Flap boxes is crucial for ensuring a secure closure. Here’s a breakdown with three examples:

1. Apparel Box (Shirt Box):

Material: Medium-weight cardboard (e.g., 24 pt. SBS – Solid Bleached Sulfate) offers a good balance between cost and rigidity. It’s strong enough to hold the shape of the box and create a perfect fit for the flaps.

Rigidity: The cardboard should be stiff enough to maintain its form and prevent bending of the flaps during use. However, excessive rigidity might make the box feel bulky.

Example: A dress shirt box wouldn’t require heavy-duty cardboard like a shoebox. A medium-weight material with well-designed flaps (discussed later) can provide a secure closure for shirts.

2. Cosmetic Box (Lipstick Tube Box):

Material: Thicker cardboard (e.g., 32 pt. SBS) or even rigid paperboard is recommended for a premium look and enhanced security. The thicker material creates a sturdier box and tighter friction fit for the flaps.

Rigidity: Opt for a more rigid material to ensure the box maintains its shape and the flaps hold their form, especially if the lipstick tube has any weight.

Example: A lipstick box needs to protect the delicate product and offer a luxurious feel. Thicker cardboard with a slight increase in rigidity can achieve both.

3. Gift Box (For a Book):

Material: Here, a balance between aesthetics and functionality is key. You might consider a slightly thicker cardboard (e.g., 28 pt. SBS) with a textured or patterned finish to enhance the visual appeal.

Rigidity: Moderate rigidity is ideal. The box should be sturdy enough to hold the book’s weight without collapsing, but the flaps should still be easy to fold and tuck in for a smooth closure.

Example: A gift box for a book needs to be visually appealing while offering enough protection. A well-designed box with a slightly thicker material can achieve both.

Flap Design

1. Flap Size:

Ensure that the flaps extend slightly beyond the slots on both sides of the box for a snug fit. The ideal extension distance depends on the product weight and desired security level. However, be mindful not to make the flaps too large, as this can detract from the box’s visual appeal. Strive to strike a balance between complete coverage and a visually pleasing design.

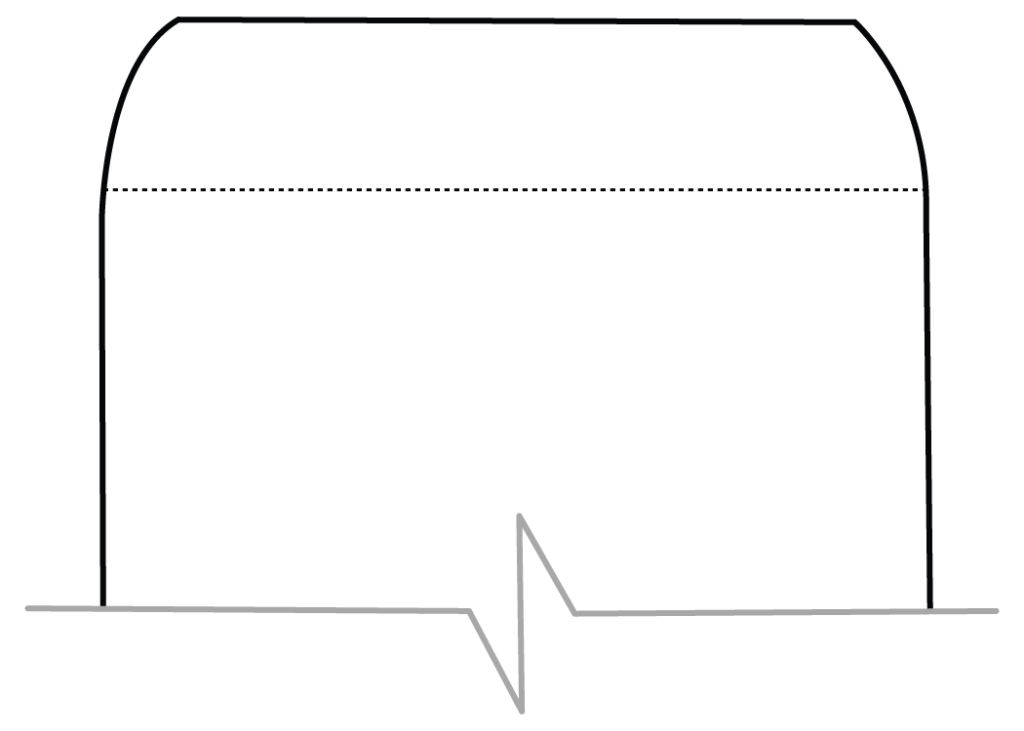

2. Flap Shape:

Basic rectangular flaps can work well, but consider incorporating features for a more secure fit. Adding small notches or protrusions on the leading edge of the flaps can create a puzzle-piece effect when they interlock with designated slots on the box. This enhances the friction fit and makes it more difficult for the flaps to become dislodged.

For a premium look and potentially a tighter fit, consider flaps with curved edges that follow the box’s shape. This design can be particularly suitable for cylindrical or rounded boxes.

For products requiring a very tight seal, like food boxes, consider a design with a flange along the leading edge of the flap. This flange creates a lip that rests on the top of the box before tucking into the slot, adding an extra barrier against external air or leaks.

Applications of Friction Fit Tuck Flap

A Friction Fit Tuck Flap offers a versatile closure option suitable for a wide range of products. Here are some common applications:

Apparel

- Shirt boxes

- Shoe boxes

- Hat boxes

- Jewelry boxes

- Scarf boxes

- Purse/Handbag boxes

Beauty Products

- Makeup boxes (eyeshadow palettes, lipstick tubes)

- Skincare product boxes (creams, lotions, serums)

- Perfume boxes

- Bath and body product boxes (soaps, bath bombs)

- Hair care product boxes (shampoo, conditioner)

Electronics and Gadgets

- Boxes for mobile phones and accessories (cases, chargers)

- Earphone/Headphone boxes

- Watch Boxes

- Small electronic device boxes (USB drives, smart speakers)

Food and Beverages

- Boxes for baked goods (cookies, pastries) Consider limitations for air-tightness

- Candy boxes Consider limitations for air-tightness

- Stationery & Office Supplies:

- Greeting card boxes

- Photo album boxes

- Pen and pencil boxes

- Notebook and journal boxes

- Desk organizer boxes

Other Applications

- Gift boxes (for various products)

- Pharmaceutical and medical product boxes (for non-critical items) Consider limitations for tamper-evident needs

- Light toy boxes (puzzles, board games)

- Craft supply boxes

- Apparel care product boxes (stain removers, laundry detergent)

Remember, the suitability of a Friction Fit Tuck Flap for your specific product depends on its weight, value, and need for a tamper-evident seal. However, with careful design considerations and material selection, a Friction Fit Tuck Flap can be a secure, user-friendly, and aesthetically pleasing closure option for a wide range of custom packaging needs.

No products in the cart.

No products in the cart.