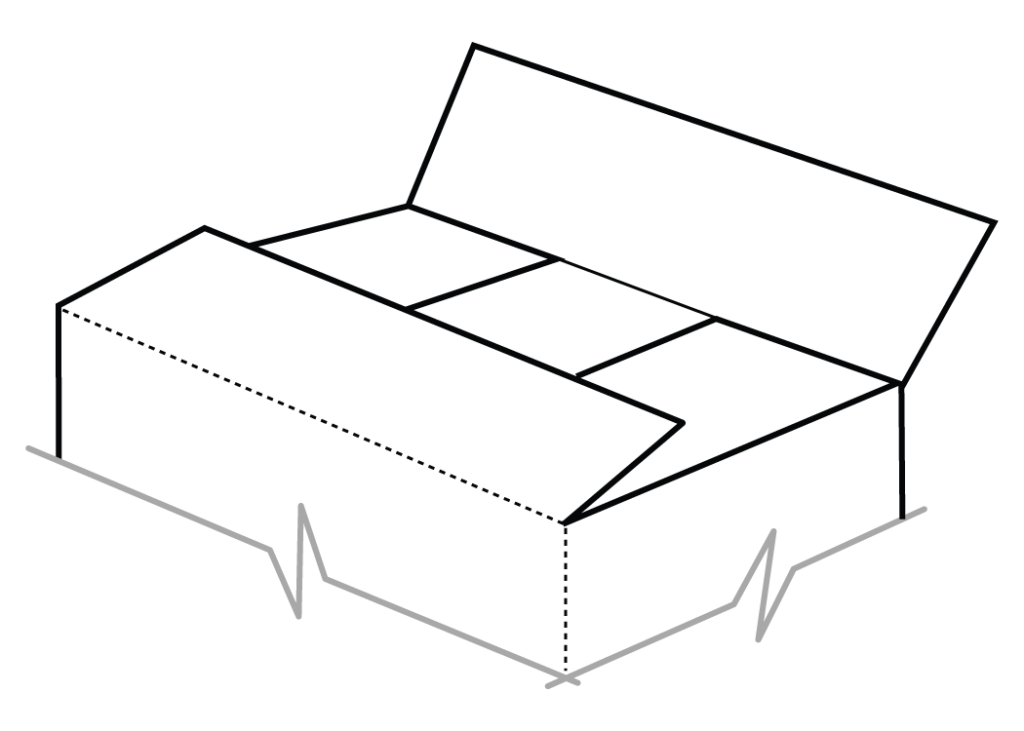

A simple tuck flap closure is a type of box closure that utilizes four flaps of equal length to create a sealed container. These flaps include two on the top (major and minor) and two on the bottom (major and minor). The flaps are folded along their designated crease lines, bringing them toward the center of the box.

To secure the closure, tape or adhesive is applied to the meeting point of the flaps along the top and/or bottom of the box, depending on the desired strength and security. The slotted flap is ideally suited for folding carton boxes and corrugated boxes.

Advantages of Slotted Flap

Distribution of Compression Forces

Slotted flaps effectively distribute compression forces across the entire box structure during stacking. This reduces stress concentration on specific points and minimizes the risk of box collapse under load.

Simple Folding Mechanism

The basic design of slotted flaps requires minimal assembly steps, making them ideal for manual or automated packaging lines. This translates to faster packing times and increased production efficiency.

Disadvantages of Slotted Flap

Minimal Tamper Evident Features

The primary disadvantage of Slotted Flap is its lack of built-in tamper-evident features. Since the flaps don’t overlap or lock, unauthorized access is relatively easy.

Non-Resealable Design

Slotted Flap is not designed for multiple usage scenarios. Once opened, the box remains open and requires additional tape or adhesives for resealing. This can be inconvenient for consumers who might need to access the product multiple times.

By understanding these limitations, you can make an informed decision about whether Slotted Flap is suitable for your application.

They are a good choice for:

- Lightweight, non-critical products where basic containment is the primary concern.

- Low-volume packaging where manual assembly is the norm.

- Applications where cost-effectiveness is paramount.

Design Considerations for Slotted Flap Closures

Material Strength

Choose cardboard with an appropriate ECT (Edge Crush Test) rating based on the weight of the product being packaged. Higher ECT ratings provide better stacking strength.

Single-Wall vs. Double-Wall

For heavier products or those requiring extra rigidity, consider double-wall cardboard for increased stacking strength and crush resistance.

Flap Area for Printing

Consider the surface area available on the flaps for branding elements like logos or product information.

By carefully considering these design considerations, you can create a slotted flap closure that is not only functional but also cost-effective, secure, and most importantly, matches your branding goals. Consulting with a packaging engineer can be highly beneficial to ensure the chosen design offers the optimal performance for your specific product and application.

Applications of Slotted Flap

Food & Beverage:

- Custom Cereals Box

- Custom Pasta Box

- Custom Cookies Box

- Custom Crackers Box

- Custom Powdered Drink Mixes Box

- Custom Tea Bags Box

- Custom Coffee bags

Household Goods:

- Personal Care Products Box

- Stationery & Office Supplies Box

- Cleaning Supplies Box

- Disposable Products Box

- Hardware & Tools Box

Pharmaceutical & Medical:

- Over-the-counter Medications Box

- Medical Supplies Box

No products in the cart.

No products in the cart.