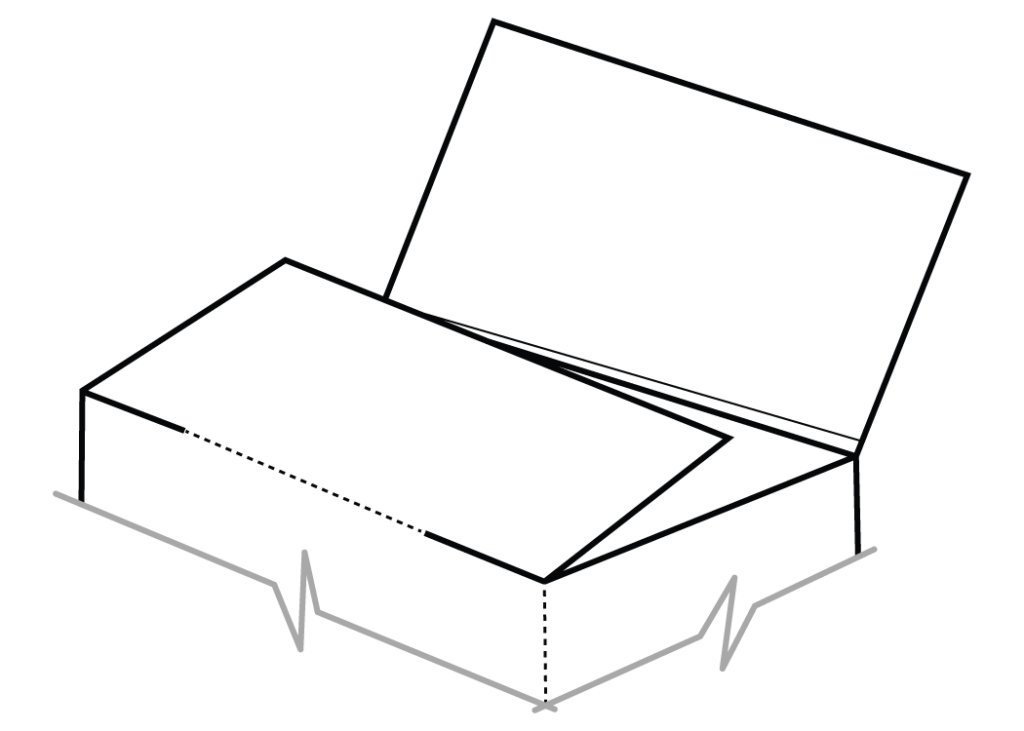

The Full Overlap Closure features two full-length flaps, typically the same width as the box’s depth, that completely cover each other at the top and/or bottom. This design creates a double thickness of material at the closure point, making boxes exceptionally strong and stable. The Full Overlap primarily relies on adhesive (glue) applied to designated areas of the flaps for a permanent closure.

Advantages of Full Overlap Closure

Enhanced Strength

The double thickness created by the overlapping flaps significantly increases the box’s ability to withstand stacking and compression forces. This is crucial for protecting heavy or fragile items during transport and storage.

Improved Stability

The Full Overlap closure distributes weight more evenly across the top and/or bottom of the box. This reduces the risk of sagging or collapse, particularly when filled with unevenly distributed weight.

Superior Tamper Evident Closure

Since the Full Overlap closure relies on adhesive, tampering with the box would be readily apparent. This discourages product theft or substitution and provides reassurance about product integrity.

Efficient Sealing

The Full Overlap ensures a complete and secure closure, minimizing the risk of gaps or leaks. Full Overlap Closure is especially beneficial for products sensitive to moisture, dust, or other contaminants.

Streamlined Production

Full Overlap Closure can be automated in the packaging process, facilitating faster and more consistent box assembly compared to some alternative closure methods.

Disadvantages of Full Overlap Closure

Potential for Adhesive Failure

The Full Overlap Closure relies solely on adhesive for a secure seal. Improper application, weak adhesive, or extreme temperatures could compromise the seal, leading to box failure or product contamination.

Limited Re-openability

Once the adhesive cures, the Full Overlap Closure becomes permanent. This makes it difficult to re-open the box for inspections or returns without damaging the box or requiring additional tools.

Design Considerations

Board Strength

Since Full Overlap Closure relies on the double layer for strength, choose a cardboard material with sufficient strength for the intended weight of the contents.

Adhesive Compatibility

Ensure the chosen adhesive is compatible with the cardboard material and will create a strong, lasting bond. Consider factors like drying time, temperature resistance, and potential interactions with the product being packaged.

Flap Stiffness

Flaps should be stiff enough to maintain their shape during filling and stacking but not so rigid that they hinder box folding or automated assembly.

Applications of Full Overlap Closure

Food and Beverage:

- Dry goods: Cereals, pasta, rice, snacks

- Bakery items: Cookies, crackers, pastries

- Confectionery: Candy, chocolates

- Beverage cartons: Juice, milk, broth

- Frozen food packaging

Cosmetics and Personal Care:

- Skincare products: Lotions, creams, serums

- Hair care products: Shampoos, conditioners, styling products

- Makeup products: Powders, foundations, lipsticks

- Fragrances: Perfumes, colognes

- Toiletries: Soaps, deodorants, shaving products

Pharmaceuticals and Medical Supplies:

- Prescription medications

- Over-the-counter drugs

- Medical devices and equipment

- Bandages and first-aid kits

Industrial and Manufacturing:

- Electronic components

- Automotive parts

- Hardware and tools

- Machinery components

- Chemicals and hazardous materials

No products in the cart.

No products in the cart.