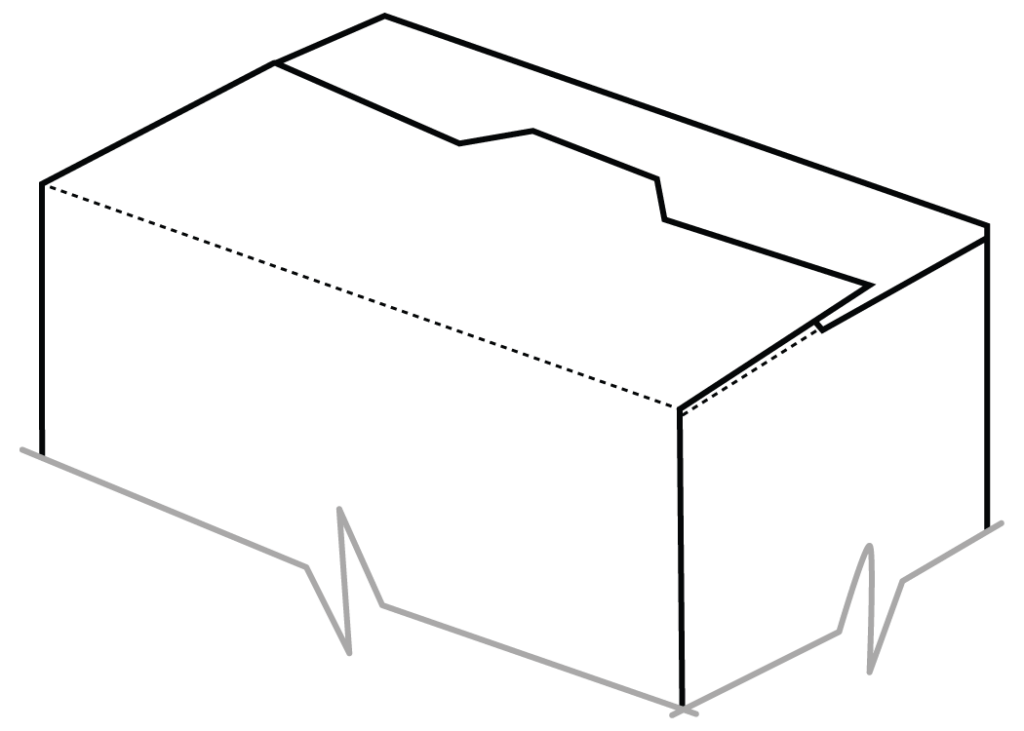

A Partial Overlap Seal End Closure (POSE) is a type of closure used for box ends, characterized by the following:

Flap Coverage: The flaps on the top and bottom of the box meet and overlap by a designated area, but they do not completely cover the entire end of the box. This designated overlap area is typically defined by pre-creased or scored lines on the flaps.

Sealing Mechanism: The overlapping flaps are secured using an adhesive applied to the designated overlap zone. This adhesive creates a sealed closure at the ends of the box, preventing contents from spilling or falling out.

Partial Overlap Seal End Closure differs from Full Overlap Seal End (FOSE) closures where the flaps completely cover the box ends, overlapping each other significantly.

Advantages of Partial Overlap Seal End Closure

Faster Production Lines

The simpler design of Partial Overlap Seal End Closure allows for more efficient folding and sealing mechanisms compared to FOSE closures. This streamlined process translates to faster production speeds on automated packaging lines, increasing overall output and efficiency.

Clean Lines and Modern Look

Partial Overlap Seal End Closure can offer a clean and modern aesthetic due to the minimal flap overlap. This can be a desirable attribute for brands seeking a sleek and contemporary look for their packaging.

Reduced Cardboard Waste

Compared to Full Overlap Seal End (FOSE) closures, Partial Overlap Seal End Closure designs utilize less cardboard. The flaps fold over the box end with minimal overlap, minimizing excess material used in the closure. This results in cost savings on cardboard and a more sustainable packaging approach.

Reliable Sealing

While Partial Overlap Seal End Closure uses less material, they can still create a secure seal when designed properly. The use of high-quality adhesives and strategically placed folds ensures the box remains closed during transport and on store shelves.

Disadvantages of Partial Overlap Seal End Closure

Potential for Leaks or Tears

Due to the reduced overlap area compared to FOSE closures, Partial Overlap Seal End Closure might be slightly more susceptible to leaks or tears, especially if the box is overloaded or experiences rough handling during transport.

Operator Error

During manual packing, workers might not apply enough pressure or ensure proper alignment when folding and sealing the Partial Overlap Seal End Closure. This can lead to incomplete seals or gaps that compromise the integrity of the box.

Difficult to Reopen

Some recloseable Partial Overlap Seal End Closure designs might be challenging to reopen, especially for users with limited dexterity. This can be frustrating for consumers who need to access the product multiple times.

Design Considerations

Box Size & Weight Capacity

The size and weight a box needs to handle directly impact the required panel strength. Larger boxes or those carrying heavier contents necessitate stiffer cardboard and potentially wider overlap areas for the Partial Overlap Seal End Closure to achieve a secure seal. This is because wider flaps with more adhesive coverage distribute stress more evenly and resist bulging under pressure.

Material Efficiency

Partial Overlap Seal End Closure uses less cardboard compared to FOSE designs, promoting material efficiency. However, achieving a strong seal with minimal material requires careful planning. Factors like the type of adhesive, how it’s applied, and the rigidity of the panels are essential.

Using high-performance adhesives allows for a narrower overlap area while maintaining seal strength. Also, strategically placed creases on the flaps can stiffen the panels, allowing for a narrower overlap without compromising the integrity of the box.

For example, a Partial Overlap Seal End Closure for a box containing fragile light bulbs might use a high-strength adhesive with a narrow overlap area to minimize cardboard usage. Strategic creases on the flaps ensure the panels can withstand compression during shipping without compromising the seal or damaging the bulbs.

Product Characteristics and Recloseability

The packaged product type can influence the Partial Overlap Seal End Closure design. Products requiring reclose-ability might benefit from specific adhesive choices or strategically placed tear strips on the flaps. Additionally, for products sensitive to moisture or oxygen, the designated overlap area might need to be wider to accommodate additional sealing layers for enhanced barrier properties.

Applications of Partial Overlap Seal End Closure

Food & Beverage:

- Dry Food Products

- Confectionery

- Frozen Food

Household Goods:

- Personal Care Products

- Stationery & Office Supplies:

- Cleaning Supplies

- Disposable Products

- Hardware Tools

Pharmaceutical & Medical:

- Over-the-counter Medications

- Medical Supplies

No products in the cart.

No products in the cart.