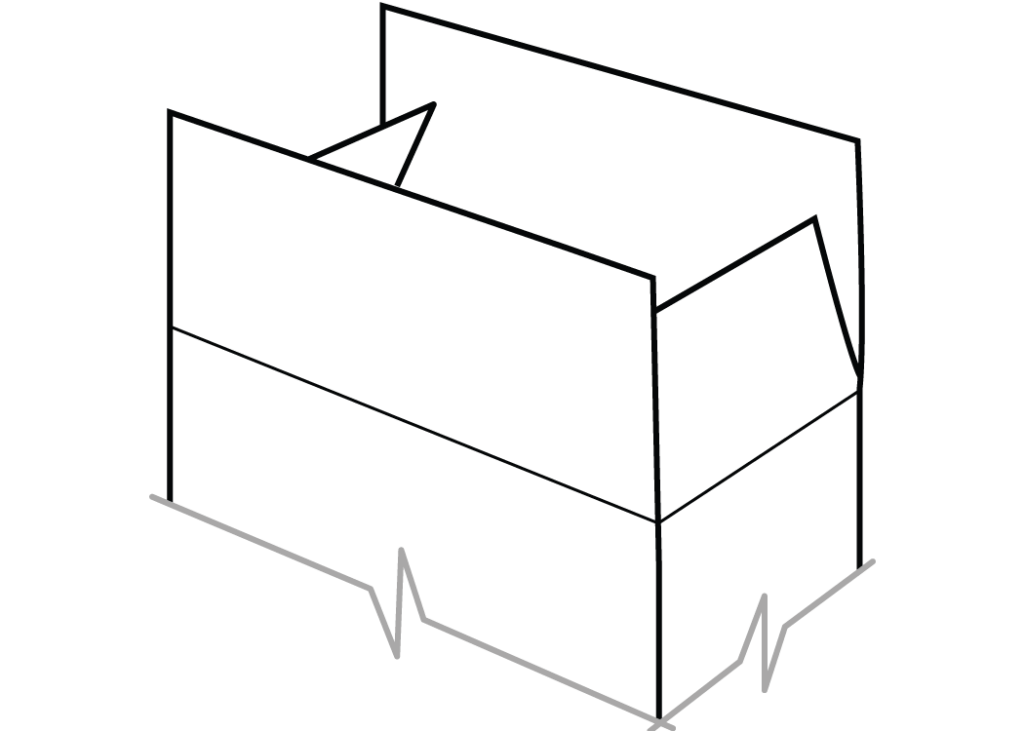

A Seal End Closure is a popular closure type for boxes, particularly folding cartons. These boxes feature flaps on both the top and bottom ends, with additional dust flaps tucked inside. The top flaps come pre-glued, creating a secure seal when folded down over the box. This closure method offers a clean and professional finish, making it ideal for a variety of products.

Benefits of Seal End Closures

Seal End Closures provide a multitude of advantages for both brands and consumers:

Tamper Evident

The pre-glued nature of the seal makes it evident that someone has tampered with the box. This is crucial for industries like pharmaceuticals and food & beverage, where product integrity is paramount.

Secure Seal

The adhesive strip forms a strong and reliable bond, ensuring your product remains securely enclosed during transport and storage.

Faster Packaging Speeds

Every second counts in a fast-paced production environment. Seal End Closures streamline the packaging process. With no fiddling with tape or struggling with clasps, employees can quickly and efficiently assemble boxes, leading to increased productivity and cost savings in the long run.

Reduced Labor Costs

The beauty of Seal End Closures lies in their simplicity. There’s no need for extra assembly steps or training for employees on complex closure methods. Simply fold the flaps and press – it’s that easy!

Presentation Appeal

Packaging is the first impression a customer has of your brand. Seal End Closures convey a sense of professionalism and attention to detail. The secure closure and clean lines subconsciously communicate that your brand cares about quality and presentation. No more worrying about flimsy flaps or loose closures!

Disadvantages of Seal End Closures

Weight Restrictions

Seal End Closures are generally ideal for lighter to moderately weighted products. The adhesive strength might not be sufficient for very heavy items, especially during rigorous transportation. For such products, reinforcing the closure with additional tape or opting for a sturdier closure method might be necessary.

Limited Re-sealability

Standard Seal End Closures are typically designed for single use. The pre-glued flaps create a strong initial seal, but once opened, they might not re-seal as effectively.

If resealability is a crucial aspect of your product (like resealable snack pouches), you might need to explore alternative closure options.

Material Compatibility

For optimal performance, the adhesive on the Seal End Closure needs to be compatible with the box material. While they work well with standard cardboard and paperboard boxes, using them with specific materials like certain plastics or non-porous surfaces might require additional testing to ensure a secure bond.

Applications for Seal End Closures

Food and Beverage:

- Bakery goods (cookies, pastries, bread)

- Snacks (chips, pretzels, candy)

- Cereal boxes

- Coffee and tea containers

- Meal kits and pre-packaged meals

- Frozen food packaging

Pharmaceuticals and Medical Supplies:

- Over-the-counter medications

- Prescription drugs

- Bandages and first-aid kits

- Medical wipes and hygiene products

- Syringes and other medical equipment (depending on weight)

Personal Care:

- Skincare products (creams, lotions, serums)

- Makeup palettes and individual products

- Hair care items (shampoo, conditioner, styling products)

- Bath and body products (soaps, lotions, bath bombs)

- Fragrances and colognes (smaller bottles)

Apparel and Fashion:

- T-shirts and other clothing items (folded)

- Hats and scarves

- Jewelry boxes

- Shoe boxes (depending on weight and size)

- Handbags and clutches (depending on size and material)

Electronics and Office Supplies:

- Small electronic devices (earphones, chargers, USB drives)

- Stationery items (pens, pencils, notebooks)

- Printer cartridges (depending on weight)

- Photo albums and scrapbooks

- Greeting cards and invitations

No products in the cart.

No products in the cart.