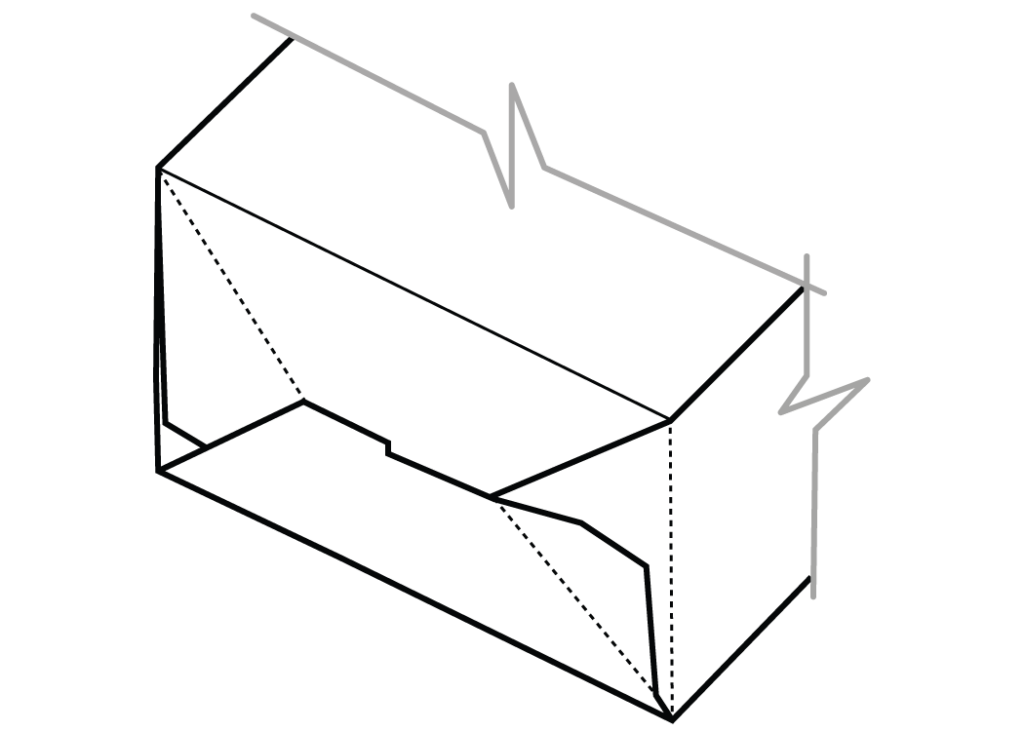

Auto bottom closures are for quick and hassle-free assembly. The panels are pre-glued with a strong adhesive, eliminating the need for tape, glue, or additional tools. Simply fold the panels along the pre-scored lines, and the interlocking design creates a secure bottom closure.

Advantages of Auto Bottom Closures

Faster Assembly

Compared to traditional closures that require taping or gluing the bottom flaps, auto bottom closures have a pre-glued interlocking design. This construction allows for quick and effortless assembly by simply folding the panels along designated creases. Auto Bottom closures save significant time and labor, especially for high-volume packaging needs.

Enhanced Efficiency

The streamlined assembly process of auto bottom closures helps in increasing efficiency in your packaging workflow. Less time spent assembling closures means more time can be dedicated to other crucial tasks in your operation.

Strong and Secure Closures

The design of the auto bottom creates sturdy and secure closures at the base of the box. Auto Bottom closures ensure your products are well-protected during storage, shipping, or handling.

Cost-Effective

While the upfront cost of auto bottom closures might be slightly higher than traditional closures due to the pre-glued feature, the time saved on assembly can result in cost savings in the long run. Additionally, eliminating the need for tape or glue reduces associated material costs.

Clean and Professional Presentation

Auto bottom closures offer a clean and professional appearance. The pre-glued design eliminates the need for visible tape or glue marks on the outside of the box, contributing to a more polished presentation for your brand or product.

Disadvantages of Auto-bottom Closures

Limited Customization

Auto bottom closures typically come in pre-determined sizes and styles due to the pre-glued interlocking design. This limits your ability to customize the box to perfectly fit your specific product or branding needs. For situations requiring a unique size or intricate closure design, auto bottom closures might not be the most suitable option.

Potential for Assembly Errors

Although designed for easy assembly, there’s a slight chance of misfolding the panels or not properly engaging the interlocking closures on auto bottom closures. This can lead to less secure closures or a weakened box structure. While proper training and clear instructions can minimize this risk, it’s a factor to consider compared to traditional closures where assembly errors are more easily identified and corrected.

Applications of Auto Bottom Closures

E-commerce and Retail:

- Shipping boxes

- Product packaging

- Gift boxes

- Subscription box services

Food and Beverage:

- Food packaging

- Take-out containers

Manufacturing and Industrial:

- Parts storage

- Assembly line packaging

- Tool storage

Home and Office:

- Storage boxes

- Moving Boxes

- Craft and hobby supplies

- Gift wrapping and presentation

No products in the cart.

No products in the cart.