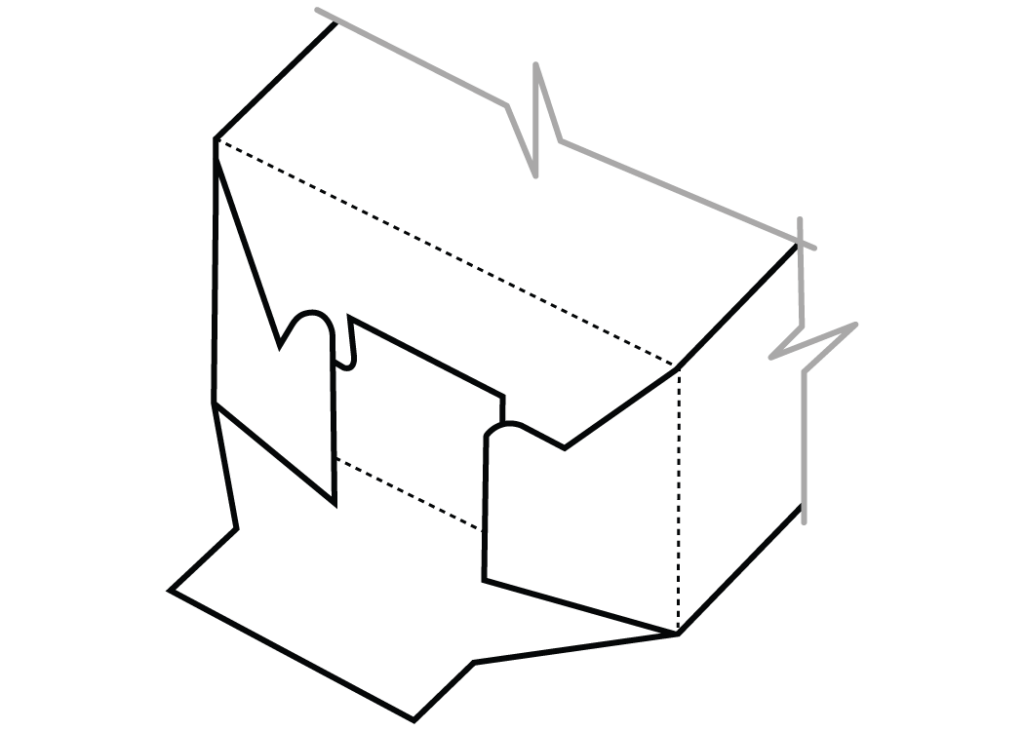

A snap lock closure is a mechanical fastening system that has four flaps that fold down from the lid, and each flap has a little bump called a “tab” sticking out. On the bottom part of the box, there are matching slots where these tabs fit snugly. Snap Lock Closure offers a simple yet clever way to keep your stuff safe and easy to open again when you need it.

Advantages of Snap Lock Closure

User-Friendly Operation

Snap Lock Closure requires minimal effort to operate. Folding and snapping the closure is simple and intuitive. This way, users of any age or ability can easily benefit from the Snap Lock Closure applications.

Secure Hold

Despite their ease of use, Snap Lock Closure provides reliable hold. The interlocking tabs prevent accidental opening and keep contents secure. This means users don’t have to worry about unsure handling even under mild shaking or impacts.

Reusable Closure

Unlike adhesive closures, snap locks can be opened and closed repeatedly without losing their effectiveness. This makes them ideal for applications requiring frequent access to the contents.

Potential for Automation

The standardized nature of snap locks makes them suitable for automation in high-volume production lines. Machines can efficiently fold and snap the closures, improving production speed and consistency.

Visually Appealing

Snap lock closures can be designed with aesthetics in mind by using various materials and finishes to enhance the visual appeal of the packaging. For example, instead of using plain plastic or cardboard, manufacturers may opt for materials such as metallic finishes, glossy coatings, or textured surfaces for extra glamor!

Disadvantages of Snap Lock Closure

Strength Limitations

The locking strength of a snap lock depends on the material and design. Flimsy materials or designs with shallow slots might not be suitable for heavy or bulky items, as they could potentially break under pressure.

Potential for Accidental Opening

Depending on the design and user handling, snap locks might open accidentally if not engaged firmly. This could be a concern for applications where accidental spillage or loss of contents is critical.

Size Constraints

The presence of the tabs and slots can eat into usable space within the container compared to other closure methods. This might be a limitation for applications requiring maximum internal space utilization.

Wear and Tear

With repeated use, the tabs and slots on a snap lock closure can experience wear and tear. This can eventually lead to a less secure hold or even breakage, depending on the material and usage frequency.

Applications of Snap Lock Closure

Food and Beverage:

- Food storage containers

- Lunch boxes

- Pouches for snacks, condiments, or baby food

Household and Personal Care:

- Cosmetic and toiletry containers

- Detergent and cleaning supplies

- First-aid kits

- Jewelry boxes and travel cases

- Stationery and office supplies

Industrial and Manufacturing:

- Toolboxes and organizer cases

- Parts bins and storage containers

- Electrical enclosures

- Medical equipment cases

No products in the cart.

No products in the cart.